A continuation of Nibble 33 on Compact Discs

References and Further info

www.alldatasheet.com - a place to find the datasheets of microchips

Technology Connections CD playlist - where Alex dissects a CD player similar to the one here (its his video that led to me choosing to do a 1980s Philips model)

What format are audio CDs in? An explanation of the CDA and CD-DA audio CD format (bandcds.co.uk)

https://www.dutchaudioclassics.nl/Philips_cdm2_cd_mechanism/

https://www.dutchaudioclassics.nl/Philips-TDA1541_A-Monolithic-Dual-16-Bit-D-A-Converter/

https://dutchaudioclassics.nl/Philips-oversampling-system-for-compact-disc-decoding/

https://dindiki.com/?oversampling

Audio Compact Disc Player (gsu.edu)

How Do Compact Discs (CDs) Work? | ElectroSchematics.com

The Anatomy of a Compact Disc

player

The CD player was a marvel of

technology back in the 1980s, marrying lasers and cutting-edge computer

processing. While most home computers at the time were still processing things

in 8-bits, CD players were processing data in 16-bit chunks, at a rate of

1,411,200 bits per second. It had to, to play high-quality digital sound. While

reading the disc, the laser’s light is also monitored to check if it’s in focus,

following the tracks on the disc, and correct itself accordingly. After

receiving the disc’s data, via photodiodes, information is retrieved along with

the music about the disc’s number of tracks and how fast the disc needs to spin

to read it. In more advanced CD players, additional information about how long each

track is, the name of the artists and songs, and (sometimes, especially for

karaoke) graphics and lyrics are retrieved. After some error correction, the

binary numbers are translated into a varying electric current, which is then amplified

and drives the speaker(s).

Philips CD371 (1987)

Also sold as the Radiola CD 1371 and the Erres CD 1371, this is a low-cost component CD player, made for those who wanted to update their pre-existing hi-fi systems. It can be programmed to play, in whatever order, up to 20 tracks. It originally sold in the UK for £179.99.

WARNING - LASERS

Most CD players, like this one,

are considered a “Class 1 Laser Product” because the laser is not visible from

the outside while in use, meaning no danger to people’s vision … unless you

take it apart, hence this warning sticker.

Motorola MC68HC05C4 8-bit

microprocessor

This is a custom-made 8-bit processor chip, which controls everything. It contains 8.192KB of memory, in the form of – 32 one-byte input/output registers, 4.156KB of ROM, 240 bytes of “self-check” ROM, 176 bytes of static RAM and 3.588KB “unused.”

Photo Diode Signal Processor

This chip, the Philips TDA5708, amplifies the signal from the laser sensor and monitors their output to detect errors caused by an out of focus/alinement lens.

Radial Error Processor

This chip, the Philips TDA5709, takes data from the photo diode signal processer and uses it to control the radial motor to correct tracking errors in the laser.

Decoder Chip

This chip, the Philips SAA7210, reverses the EFM process, processes the subcode in the data, performs CIRC error correction, controls the speed of the spindle motor, and detects and masks read errors.

Q Channel Subcode Data

This data tells the CD player what kind of audio it is playing (is it stereo?), what track is playing and how long it is.

µPD41416C-20 dynamic NMOS RAM

chip

This chip contains 8.192KB of dynamic N-channel Metal Oxide Semiconductor Random Access Memory, in the form of 16,384 4-bit nibbles. Its here where the decoder chip places its work while processing.

Digital Filter

This chip, the Philips SAA7220, is

where the data from the decoder and DAC is “oversampled” four times to reduce

distortion of the audio. It also interjects or mutes data if there is an error.

It contains 480 bits of RAM and two finite impulse response transversal filters,

one for each stereo channel.

Digital-to-Analogue Convertor

This chip, the Philips TDA1541, is

a stereo 16-bit digital-to-analogue converter. It’s in this chip that the

binary numbers encoded on the disc are converted into a varying electrical

signal, which drives the speakers.

Display

The LED display is operated by two display driver chips, the MM58348 to control the anodes, and the MAB8441 8-bit microcontroller (containing 4KB of ROM and 128 bytes of RAM) to control the grids.

Output

Like many affordable CD players, this model only has standard analogue stereo RCA jacks at the rear and a headphone jack at the front. But some thought copper wiring was too old-fashioned for the CD. In 1983, Toshiba introduced the TOSLINK fibre optic-based audio connector, which sent information digitally via light.

Closing the Drawer

After ejecting, the CD drawer can be closed by neither pressing the “open/close” button on the front panel or by just pushing the drawer in a bit. When you do so, a notch in the drawer pushes a lever, which pushes another lever, which presses a button on the motherboard. This button activates the tray motor to close the drawer.

To keep the CD flat on the spindle, a spring-loaded clamp holds the disc down.

On/Off Button

In this model, the main power on/off

switch is far back on the motherboard, close to where the mains cable enters

the player. A long plastic lever connects it to the spring-loaded “on/off”

button on the front panel. Why? A cost-cutting measure, or is it because there

was no room for an actual switch there, because of the headphone jack?

Reading a CD with Light

The main component of a CD player is the optical pick-up

mechanism. It’s a complicated set up, made up of a laser, some prisms and lenses

attached to some magnetic coils, and a set of photodiodes. It’s designed to

always keep the laser beam focused on the trail of pits on the CD. While the CD

spins, the laser’s reflected output is monitored constantly to check if its in

focus. If it isn’t, photodiodes detecting the flaws send signals to a circuit

which sends signals to the coils, which move the lens to adjust the laser’s

focus accordingly. In the early years of the format, Philips and Sony created

two different designs of optical pick up. Early Philips CD players used a swing

arm mechanism, which moved the pick-up in a manner similar to a tonearm on a

record player. Sony created a linear mechanism, where the pick-up is moved

along a straight rail by a rotating gear or linear motor. The optics did the

fine tuning. The latter became the default design used on almost all later

optical disc-playing devices. Although they are different in details, they

fundamentally work the same way.

T-Type 3-Beam Optical Pickup

This design of pickup is called the T-type optical pickup

(or TOP, in short). It is used in many large optical disc drives, including the

first Sony CD player (the CDP-101). It’s the design you mostly see in many

explanations on how a CD player works, except this one is more detailed. Pictured

here is a three-beam set-up, developed by Sony.

How it Works

In this set up, the laser light travels through a diffraction grating, which creates a main beam and two side beams. The light then enters a polarizing “beam splitter” prism, where the bean is split into two. One going to the sensor, the other to the disc. The prism is a polarizing filter, only allowing vertically-aligned light waves through. The beam travelling to the disc is concentrated by the collimator and then has its beams bent 45° by a quarter wave plate. This light is finally focused onto the disc’s pits by a simple convex lens. When reflected back from the disc, the light is bent again by the quarter wave plate, bending it 90° completely, making the reflected beam horizontally polarized. After leaving the collimator, the beam converges on the slating surface of the prism. Now horizontally polarized, the beam is reflected internally by the slanted surface of the prism towards the sensors. Along the way, a cylindrical lens focuses the beam in one plane onto the sensors. This creates a circle shape on the sensors if in focus. If not, it’ll be elliptical. The difference between intensities detected by the sensors is used to control the position of the top lens for continuous focus and tracking of the pits. The two side beams are for two side spot detectors on each side of the main detector array. They are to detect tracking errors.

When it shines on a disc, the laser beam is 0.75mm wide. When it reaches the pits, its 1.7µm wide.

Optics

The optical components in CD and DVD players (using 780nm near-infrared and 650nm red visible light lasers) are made of glass. Other wavelengths require more exotic materials, such as lithium fluoride (for ultraviolet lasers). Blu-Ray players use a 405nm wavelength laser, which is just on the border between visible violet light and ultraviolet.

The CD is about 2mm above the objective lens inside a player

Detecting Pits

The laser changes intensity when it scans a pit on the disc. The pits are a quarter of the laser’s wavelength deep (195nm). This is so that when the light is reflected back from the land, the light waves are half a wavelength out of phase of the initial light, cancelling it out. This creates a moment of no light intensity on the sensor – ideally. In reality, the pits depth may not be precisely made. But the resulting destructive interference still produces reduced intensity.

The collimator is a two-lens set up designed to increase the diameter of a beam while reducing its divergence.

Cylindrical lens creates an elliptical shaped beam when the light is unfocused. It is round when in focus.

A prism is an optically transparent lump of material shaped to refract, disperse, or reflect light in a desired way.

Diffraction gratings are used to split beams. It is a thin plate, with one surface coated in a partially reflective film of thin metal with narrow silts spaced a few wavelengths worth apart.

The quarter wave plate is an anisotropic crystal, which beads polarized light 45°. How much it can bend depends on the wavelength of the light and how thick it is. To bend light 180°, the crystal must be as thick as the wavelength of the light been bent. As were only bending a 780nm laser 45°, this plate is only 195nm thick.

Photodiode Array

The main sensor in a CD player is a collection of

photodiodes. Why more than one? With multiple sensors, they can detect if the

light their sensing is getting out of alinement or out of focus, by variations

in their input. Single beam pickups only need four photodiodes. 3-beam pickups,

like this one, have an additional two photodiodes to aid tracking. More on this

later.

Philips RAFOC Single Beam Tracking Pickup

This CDM2 pick up is from the Philips CD371 of 1987. The CDM series of mechanisms were designed mostly for stable performance, making them well-engineered. They use a magnetic actuator mounted on a swing arm to do the tracking. Optically, it uses a single beam system, where everything is done with just one beam, working with just four photodiodes. Some audiophiles believe this mechanism is better at reading scratched discs. With a counterweight and so many moving parts, this mechanism had a speed limit in reading CDs, limiting its use in CD-ROM drives. It also would have trouble working in portable devices, only working well when stationary. The CDM2 has a resin top plate, made to reduce cost and weight while maintaining the quality of zinc-diecast versions used in earlier CDMs. It was only used in less expensive players, like the CD371, for a short time. In fact, it was replaced with the CDM4 mechanism in the CD371 in 1988.

CD players that used CDM mechanisms were made by Grundig, Magnavox,

Marantz, Schneider, Technics, and Toshiba, as well as Philips.

Radial And FOCusing unit

The “Philips RAFOC” unit achieves tracking by moving the

whole optical system, via a swing arm, operated by a radial motor.

Optics

Optically, the only differences between single beam and three-beam

systems are the lack of a diffraction grating (to split the beam), and the fact

the objective lens can only be adjusted vertically. Horizontal adjustment is

done by the swing arm moving the whole set up.

Four Diode Sensor

The Single Beam system only uses a rectangular array of four photodiodes to monitor the condition of the focus and tracking of the laser.

Sony’s “3-beam linear tracking” Flat-type Pickup

Many slimmer optical disc drives use what is called a

Flat-type optical pickup (for FOP, in short). This model KSS-220A FOP is taken

from a Sony Discman D-11 from 1990. It uses Sony’s alternative design where the

tracking is done by two systems. First, the whole optical system is moved along

a linear rack. Then, for fine tracking, the pick up’s lens is positioned

precisely by a collection of electromagnetic coils. This is aided with the side

beams used in the three-beam optical system. Sony’s design eventually became a default

design for most CD players because it was cheaper to make, and can be easily scaled

down and work in smaller, slimmer, portable devices.

The ”A” marks out this mechanism is designed for desktop

players, designed for higher drop-out performance, but low vibration

resistance. The “B” version of this mechanism is designed for

“ghetto-blasters,” with high vibration resistance, but lower drop-out performance.

Optics

The optics of a three-beam set-up include a diffraction

grating (to split the beam) and an objective lens whose vertical and horizontal

position can be adjusted by a set of electromagnetic coils.

Three-Beam Tracking

In a three-beam system, the laser beam is split into one

main beam and two side beams. The two side beams are shun about 20µm away from the main beam, on each side of the track been scanned by the

main beam. If any of these side beams come back with data from the track, it

indicates to the player that the main beam is out of alinement, thus needs

adjusting accordingly.

In addition of using a similar four photodiode array as in single-beam

systems to detect focus issues, three-beam systems employ two extra photodiodes

for detecting tracking errors from the side beams

Over time this pickup design has been modified and tailored to different forms. Some versions of it have the optics arranged differently, or have a part or two removed and replaced with one part doing the job of two parts, saving costs. But the biggest mod has been the size of the pickup itself. Been easily scalable, it has allowed the creation of thinner optical drives for use in devices like laptop computers.

Playing Sounds off a CD

So, you put a disc in a CD player

and laser scans its pits and lands and registers them as a pattern of bright

and dim signals on a photodiode. But how does that become the music coming out

the speakers? Previously, we saw the data on the CD recorded is not just the

audio, but also additional information, like where the track begins and how

fast to spin the motor? How is the data we had muddled up initially, for the

sake of bandwidth and error prevention and correction, turned back into the

audio we originally recorded? This part explores what’s going on in the

circuits inside a CD player while it plays a disc. All you see here happens in

a CD player, while playing a CD, every 3,675th of a second!

From Photodiode to Decoder

1. The RF signal coming from the photodiodes begins as a weak varying electric current. It is first fed through a current-to-voltage convertor, then the resulting voltages are amplified.

2. This signal is then fed into a waveshaper circuit. This circuit analyses the signal, in the form of an “eye pattern,” and detects its “zero crossing points,” which are used to transform the varying current into a square wave signal. The signal goes through the waveshaper multiple times, via a low-pass filter, to form a feedback loop. This is to obtain the correct slice of the “eye patten” in the form of a DC voltage in the waveshaper’s input. This forms the square wave signal, which is then fed to the EFM demodulator.

3. From the waveshaper, the signal is also fed into a phase-locked loop circuit. This is to detect the timing of the signal to synchronize the player’s clock to the data stream.

Each information frame begins with a 24-bit long “sync word.” This piece of data controls the speed of the CD’s spindle. Their frequency is compared to a fixed frequency produced by a crystal oscillator in a phase comparator. As the CD plays from lead-in to lead-out the tracks increase in length, increasing the number of frames been processed. The player will notice this and slow down the spindle motor accordingly.

Eight-to-Fourteen Modulation Demodulator

4. In the EFM demodulator 14-bit codewords are translated back into their original 8-bit symbols. A piece of ROM memory contains a look-up table, where it compares the 14-bit codewords been fed in to what 8-bit symbols they represent.

Subcodes

Its in the EFM demodulator that the subcode(s) stored in the control word of the information frames are retrieved. 98 information frames need to be read before getting one 98-bit word of subcode. After retrieval, the subcode is fed to the CD player’s main processor. This code tells the player things like, how many tracks, where are they, and how long they are.

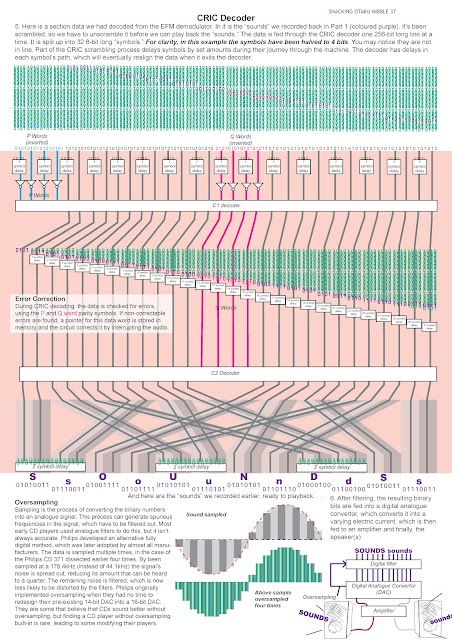

Error Correction

During CRIC decoding, the data is

checked for errors, using the P and Q word parity symbols. If non-correctable

errors are found, a pointer for this data word is stored in memory and the

circuit corrects it by interrupting the audio.

CRIC Decoder

5. Here is a section data we had decoded from the EFM demodulator. In it is the “sounds” we recorded back in Part 1 (coloured purple). It’s been scrambled, so we have to unscramble it before we can play back the “sounds.” The data is fed through the CRIC decoder one 256-bit long line at a time. It is split up into 32 8-bit long “symbols.” For clarity, in this example the symbols have been halved to 4 bits. You may notice they are not in line. Part of the CRIC scrambling process delays symbols by set amounts during their journey through the machine. The decoder has delays in each symbol’s path, which will eventually realign the data when it exits the decoder.

Oversampling

Sampling is the process of converting the binary numbers into an analogue signal. This process can generate spurious frequencies in the signal, which have to be filtered out. Most early CD players used analogue filters to do this, but it isn’t always accurate. Philips developed an alternative fully digital method, which was later adopted by almost all manufacturers. The data is sampled multiple times, in the case of the Philips CD 371 dissected earlier four times. By been sampled at a 176.4kHz (instead of 44.1kHz) the signal’s noise is spread out, reducing its amount that can be heard to a quarter. The remaining noise is filtered, which is now less likely to be distorted by the filters. Philips originally implemented oversampling when they had no time to redesign their pre-existing 14-bit DAC into a 16-bit DAC. They are some that believe that CDs sound better without oversampling, but finding a CD player without oversampling built-in is rare, leading to some modifying their players.

6. After filtering, the resulting binary bits are fed into a digital analogue convertor, which converts it into a varying electric current, which is then fed to an amplifier and finally, the speaker(s).

Comments

Post a Comment